The Cost of Building a Peanut Butter Manufacturing Plant

Peanut butter is delicious and nutritious, and is one of the most popular flavorings. Therefore, there will be many people in the world who want to build a peanut butter manufacturing plant and start a business, so do you know the cost? Let's learn more together.

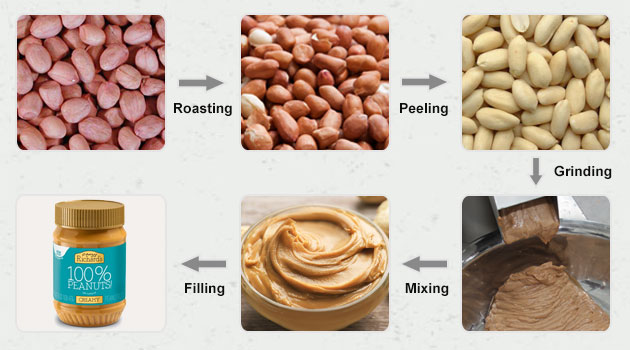

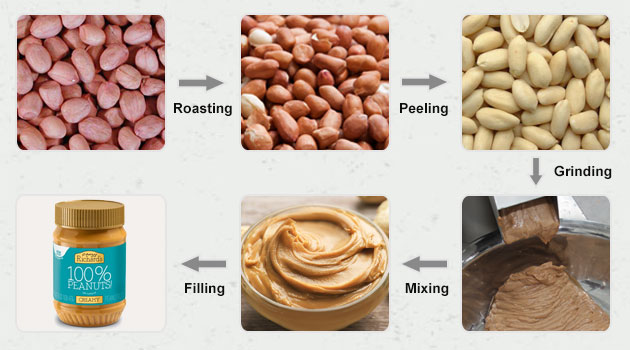

Peanut Butter Manufacturing Process:

Raw material selection → roasting → cooling → peeling → rough grinding → micro grinding → mixing → cooling → sterilization → filling

Peanut Butter Manufacturing Plant Cost:

It mainly includes several parts: plant land, construction cost, mechanical equipment, labor cost, raw material cost and transportation cost.

- 1. Before starting a business, you need to do some research on the local peanut butter processing plant to understand the approximate cost of factories of different production scales.

- 2. The most common output is 100 kg / h, 200 kg / h, 300 kg / h, 500 kg / h, 1 t / h, etc. Determine the production scale according to your budget, whether it is fully automatic or semi-automatic production.

- 3. In a region of a country, the unit price of land, labor, raw materials, and transportation is almost the same, and the cost is mainly affected by the scale of production.

- 4. Mechanical equipment is the core part, and it is also the part with larger price gap. The quality of the machines of different manufacturers is different, and the price will be different. You can choose it after your own consideration.

After the above factors are determined, the cost of a peanut butter processing plant is basically determined.

Peanut Butter Manufacturing Process:

Raw material selection → roasting → cooling → peeling → rough grinding → micro grinding → mixing → cooling → sterilization → filling

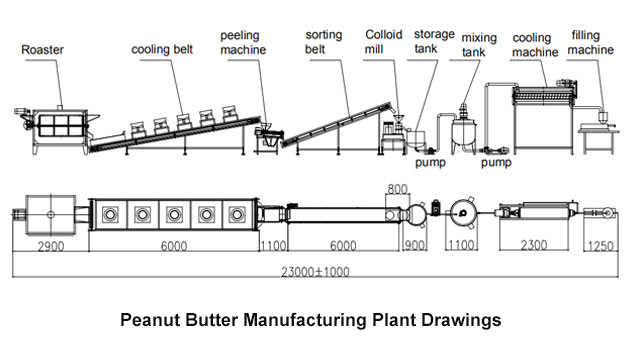

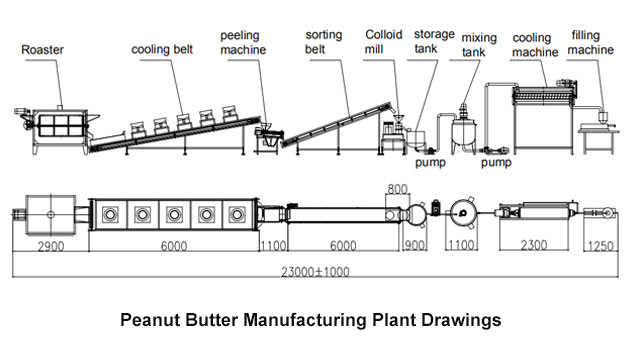

Equipment for Peanut Butter Manufacturing Plant:

(1) Roaster: roast peanuts.

(2) Cooling belt: cooling and roasting peanuts.

(3) Peeling machine: peeling the roasted peanuts, the peel kernels are automatically separated during the peeling process.

(4) Picking belt: pick unqualified peanuts and some food residues.

(5) Coarse grinder: grind peanuts for the first time.

(6) Ultra-fine film: further grinding, the processing fineness is further improved.

(7) Condenser: Cool the ground peanut butter.

(8) Degassing tank: degassing peanut butter before filling.

(9) Filling: filling in bottles or packaging in bags.

Recommended Products: Peanut Butter Production Line

Skype: serenayan666

Email: serena@machinehall.com

Whatsapp/Mobile: +8615515597212

Message