How Are Almonds Sliced Commercially?

Sliced almonds can quickly add crispy, protein and flavor to foods such as baked food (cakes, cookies, etc.), meat, salads, etc., so almond slices have a wide range of USES in the food processing industry. You will see many packaged almond slices in the supermarket retail, these almond slices are divided into different thickness, for consumers to choose according to their needs. So how are almonds sliced commercially? or how do they slice almonds?

Step 1

Blanching almonds. This is usually the first step in almond slicing, because blanching with hot water will soften almonds, so that almonds do not break when sliced. After blanching, the skin of the almonds also becomes easier to remove. The machine used in this step is called almond blanching machine, which can heat almonds to 160 degrees Fahrenheit (71 degrees Celsius).

Step 2

Removing almond skins. Commercial almond peeler machine are necessary here. It adopts the principle of rubber roller friction to remove the blanched almond skins easily, get the whole almond kernel and no damage for the almond kernel surface. Although almond peeling is an optional process, almonds that have been peeled are also easier to slice and will be more conducive to the subsequent formulation of almond slices.

Step 4

Roasting or drying almond slices. After roasting, the water in the blanched almonds can be removed. It is convenient for storage of almond slices.

In order to help you better understand this question of how are almonds sliced, let see one video first, know more about the almond slicing machine.

From this video, you can see how to make almond slices. Put almonds into the feeding hopper, and then will be cut into almond slices. The slicing thickness of almond slices is adjustable. This almond slicer can cut almonds with high automation and efficiency. So this machine can meet commercial use for almond slices production.

Step 1

Blanching almonds. This is usually the first step in almond slicing, because blanching with hot water will soften almonds, so that almonds do not break when sliced. After blanching, the skin of the almonds also becomes easier to remove. The machine used in this step is called almond blanching machine, which can heat almonds to 160 degrees Fahrenheit (71 degrees Celsius).

Step 2

Removing almond skins. Commercial almond peeler machine are necessary here. It adopts the principle of rubber roller friction to remove the blanched almond skins easily, get the whole almond kernel and no damage for the almond kernel surface. Although almond peeling is an optional process, almonds that have been peeled are also easier to slice and will be more conducive to the subsequent formulation of almond slices.

Step 3

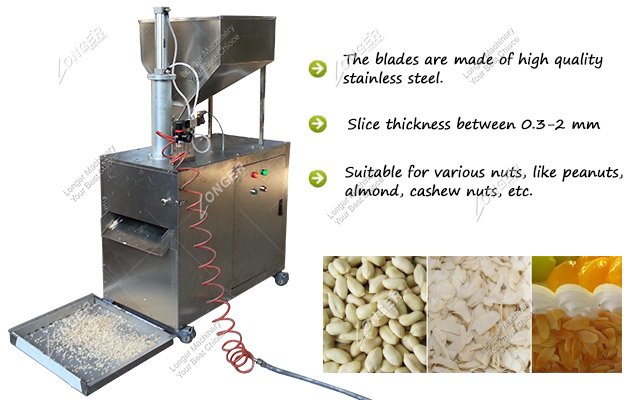

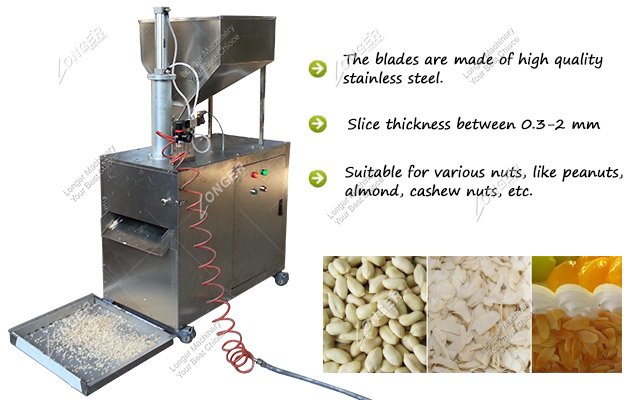

Slicing almond kernels. There is a special commercial machine, called the almond slicing machine, which can process up to 300 kg of almonds per hour, so as to meet the demand of large production in industry. Home almond slicing machine can not meet the requirements for commercial almond slices production. The thickness of cutted almond slices range from 0.3mm to 2mm.

Slicing almond kernels. There is a special commercial machine, called the almond slicing machine, which can process up to 300 kg of almonds per hour, so as to meet the demand of large production in industry. Home almond slicing machine can not meet the requirements for commercial almond slices production. The thickness of cutted almond slices range from 0.3mm to 2mm.

Step 4

Roasting or drying almond slices. After roasting, the water in the blanched almonds can be removed. It is convenient for storage of almond slices.

In order to help you better understand this question of how are almonds sliced, let see one video first, know more about the almond slicing machine.

From this video, you can see how to make almond slices. Put almonds into the feeding hopper, and then will be cut into almond slices. The slicing thickness of almond slices is adjustable. This almond slicer can cut almonds with high automation and efficiency. So this machine can meet commercial use for almond slices production.

For this almond slicing machine, slice thickness can be adjusted according to your need. The thickness of slices is from 0.2mm to 3mm. The machine is made of high quality and high speed steel grinding blade, which is very sharp and durable. The fuselage cover is made by stainless steel plate, beautiful and easy to clean.

This slicing machine can slice variety of nuts, like peanuts, almonds, cashew nuts and so on. And the nuts can’t be too dry, we need to soak the nut kernels firstly, then cut them into slices. Besides, nuts should via the selection process, which can not be mixed with sand and stones and other debris.

If you want to know more about how are almond sliced commercially, and interested in almond slicing machine, just feel free to contact us or leave your message. We can send you price, pictures, working video and parameter data.

This slicing machine can slice variety of nuts, like peanuts, almonds, cashew nuts and so on. And the nuts can’t be too dry, we need to soak the nut kernels firstly, then cut them into slices. Besides, nuts should via the selection process, which can not be mixed with sand and stones and other debris.

If you want to know more about how are almond sliced commercially, and interested in almond slicing machine, just feel free to contact us or leave your message. We can send you price, pictures, working video and parameter data.

Contact Serena:

Skype: serenayan666

Email: serena@machinehall.com

Whatsapp/Mobile: +8615515597212

Message