Automatic Cashew Nut Milk Making Processing Line in China Price

Material: Cashew Nuts

Capacity: 200-300 kg/h

Loading Port: Qingdao Port

Description: This cashew milk production line can realize automatic production from making to filling. It can also be used to produce almond milk, walnut milk, etc.

Product Features

The cashew milk processing line can realize the automatic production of the whole process from grinding to filling, and the whole process of closed production is safe and hygienic. This production line can also be used to produce almond milk, walnut milk and other nut milks, which are very popular in the market now.

Cashew Nut Milk Processing Flow:

1. Grinding: Turn on the colloid mill, add water and cashew nuts together in a certain proportion into the hopper for grinding. The machine can achieve circular grinding until you get the cashew milk fineness you need.

2. Filtration: There will be some residue in the ground cashew milk. We use a high-precision fine powder screening machine to remove the residue and obtain cashew milk with better taste.

3. Mixing: The cashew milk is piped into a mixing tank, where it is blended to heat the cashew milk.

4. Homogenization: Then the cashew milk goes into a homogenizer and is homogenized and emulsified. The rough cashew milk emulsion is processed into a fine, uniform and stable emulsion with an average fineness of less than 1 μm. The viscosity and concentration of cashews will also increase.

5. Sterilization: The refined cashew milk is transported to the UHT sterilizer for sterilization and cooling, thereby extending the shelf life.

6. Filling: Sterilized cashew milk is filled into various bottles.

Main Equipment in Cashew Milk Making Line

The whole line contains a lot of equipment, there are storage tanks, elevators, grinders, screening machines, storage tanks, mixing tanks, homogenizers, sterilizers, filling machines, capping machines, labeling machines and various pumps .

1. Cashew Nut Milk Making Machine:

It integrates various properties of machines such as homogenizer, ball mill, three-roller, shearing machine, mixer, etc., and has excellent superfine grinding, dispersing and emulsifying, homogenizing, mixing and other functions. By adjusting the gap between the stator and the rotor, the required ultra-fine crushing effect can be effectively achieved at one time (it can also be processed cyclically).

2. Cashew Milk Homogenizer:

During homogenization, cashew milk is pressed out of the slits of the homogenization valve under high pressure. Under the combined action of shear force, impact force and cavitation effect, particles such as fat globules and proteins are miniaturized to form a uniform dispersion. Increases the glossiness of cashew milk and improves stability.

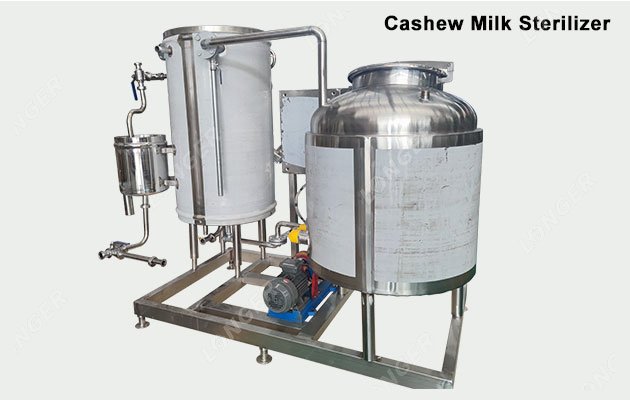

3. Cashew Milk Sterilizer:

The sterilization temperature of this sterilizer is 135-140℃, and the temperature is kept for 4 seconds to meet the commercial sterility requirements. The entire sterilization process is instantaneous at high temperature, which completely kills microorganisms and spores that can cause material corruption and deterioration, and also greatly retains the original flavor and nutrients of cashew milk.

4. Cashew Nut Milk Filling Machine

The filling machine is a fully automatic filling machine controlled by a microcomputer (PLC) programmable, photoelectric sensor, and pneumatic execution in one. Different high viscosity fluids (such as milk, yogurt, etc.) can be filled. The filling volume is easy to adjust.

Cashew Nut Milk Processing Flow:

1. Grinding: Turn on the colloid mill, add water and cashew nuts together in a certain proportion into the hopper for grinding. The machine can achieve circular grinding until you get the cashew milk fineness you need.

2. Filtration: There will be some residue in the ground cashew milk. We use a high-precision fine powder screening machine to remove the residue and obtain cashew milk with better taste.

3. Mixing: The cashew milk is piped into a mixing tank, where it is blended to heat the cashew milk.

4. Homogenization: Then the cashew milk goes into a homogenizer and is homogenized and emulsified. The rough cashew milk emulsion is processed into a fine, uniform and stable emulsion with an average fineness of less than 1 μm. The viscosity and concentration of cashews will also increase.

5. Sterilization: The refined cashew milk is transported to the UHT sterilizer for sterilization and cooling, thereby extending the shelf life.

6. Filling: Sterilized cashew milk is filled into various bottles.

Main Equipment in Cashew Milk Making Line

The whole line contains a lot of equipment, there are storage tanks, elevators, grinders, screening machines, storage tanks, mixing tanks, homogenizers, sterilizers, filling machines, capping machines, labeling machines and various pumps .

1. Cashew Nut Milk Making Machine:

It integrates various properties of machines such as homogenizer, ball mill, three-roller, shearing machine, mixer, etc., and has excellent superfine grinding, dispersing and emulsifying, homogenizing, mixing and other functions. By adjusting the gap between the stator and the rotor, the required ultra-fine crushing effect can be effectively achieved at one time (it can also be processed cyclically).

2. Cashew Milk Homogenizer:

During homogenization, cashew milk is pressed out of the slits of the homogenization valve under high pressure. Under the combined action of shear force, impact force and cavitation effect, particles such as fat globules and proteins are miniaturized to form a uniform dispersion. Increases the glossiness of cashew milk and improves stability.

3. Cashew Milk Sterilizer:

The sterilization temperature of this sterilizer is 135-140℃, and the temperature is kept for 4 seconds to meet the commercial sterility requirements. The entire sterilization process is instantaneous at high temperature, which completely kills microorganisms and spores that can cause material corruption and deterioration, and also greatly retains the original flavor and nutrients of cashew milk.

4. Cashew Nut Milk Filling Machine

The filling machine is a fully automatic filling machine controlled by a microcomputer (PLC) programmable, photoelectric sensor, and pneumatic execution in one. Different high viscosity fluids (such as milk, yogurt, etc.) can be filled. The filling volume is easy to adjust.

Technical Data

| No. | Name | Size(mm) | Qty(set) |

| 1 | Grinding Machine | 810*760*1300 | 2 |

| 2 | Filtering Machine | 800*800*890 | 1 |

| 3 | Mixing Machine | 800*1355 | 1 |

| 4 | Homogenizer | 1030*745*990 | 1 |

| 5 | Mixing Tank | 800*1355 | 2 |

| 6 | UHT sterilization machine | 2000*1200*1500 | 1 |

| 7 | Filling and Capping Machine | 1600*1450*2200 | 1 |