Cocoa to Chocolate Making Machine for Small Business

Material: Cocoa Bean

Capacity: 100-200 KG Per Hour

Loading Port: Qingdao Port

Description: The whole chocolate making machine is specially designed for small scale business. Wide template, low cost, automatic pouring, drying and other functions.

Product Features

This small scale chocolate making machine can complete the whole process from cocoa beans to chocolate molding. It can process 100-200kg of cocoa beans per hour, producing high-quality chocolate with a smooth surface and correct weighing.

This producton line is special chocolate making machine for small business. The production flow includes cocoa roasting, peeling, grinding, refining, mixing and chocolate bar moulding and so on with automatic operation.

Cocoa Bean to Chocolate Making Process:

Cocoa Bean -- Roasting -- Peeling -- Grinding -- Press - Cocoa powder grinding - Storage -- Conching -- Mixing - Moulding -- Chocolate Bar

Introduction of Small Scale Chocolate Processing Equipment:

1. Cocoa Bean Roasting Machine

The cleaned cocoa beans enter the roaster machine for roasting. Generally, the roasting temperature is between 120 and 160 degrees Celsius.

2. Cocoa Bean Peeling Machine

The roasted cocoa beans will enter the cocoa peeler and the peeling process. This process is an important part of the production of high quality chocolate sauce. After the peeling process, only cocoa kernels enter the next process.

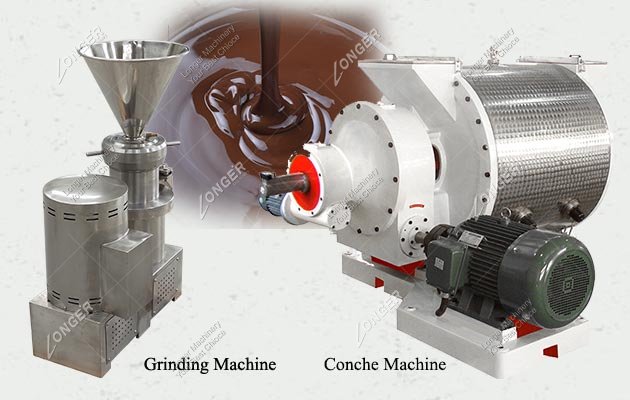

3. Cocoa Grinding and Storage Machine

Coarsely ground cocoa beans generally become slurries, which enter the slurry tank for storage. Storage temperatures generally drop to 80 degrees Celsius.

4. Cocoa Butter Press Machine

This hydraulic oil press has a high oil output rate and is also suitable for the production of peanut oil, sesame oil and almond oil. High hardness and high strength.

5. Chocolate Refiner Machine

The refiner finely grinds the chocolate slurry, which has the dual functions of grinding and refining, and achieves fine granularity and meets the requirements of chocolate production and manufacturing technology.

6. Stirring and Homogenizing Machine

Homogeneity can be achieved by continuous stirring with a stirring machine.

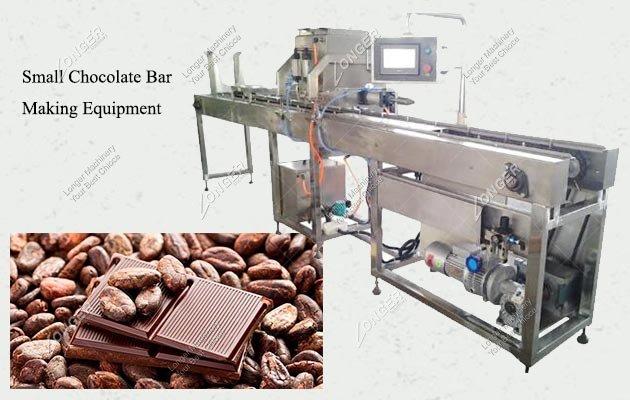

7. Small Scale Chocolate Making Machine

Chocolate moluding machine is a special equipment for quantitative pouring of chocolate. It has functions of automatic pouring, automatic drying, vibration and cooling. It can make a variety of chocolate types such as single color, double color, and filled chocolate.

The sterilization process is also essential. These are some of the equipment needed from cocoa beans to chocolate. There are also some auxiliary equipment, not listed above.

We can configure the entire chocolate making equipment according to customer requirements. Just tell me your needs, email: serena@machinehall.com

This producton line is special chocolate making machine for small business. The production flow includes cocoa roasting, peeling, grinding, refining, mixing and chocolate bar moulding and so on with automatic operation.

Cocoa Bean to Chocolate Making Process:

Cocoa Bean -- Roasting -- Peeling -- Grinding -- Press - Cocoa powder grinding - Storage -- Conching -- Mixing - Moulding -- Chocolate Bar

Introduction of Small Scale Chocolate Processing Equipment:

1. Cocoa Bean Roasting Machine

The cleaned cocoa beans enter the roaster machine for roasting. Generally, the roasting temperature is between 120 and 160 degrees Celsius.

2. Cocoa Bean Peeling Machine

The roasted cocoa beans will enter the cocoa peeler and the peeling process. This process is an important part of the production of high quality chocolate sauce. After the peeling process, only cocoa kernels enter the next process.

3. Cocoa Grinding and Storage Machine

Coarsely ground cocoa beans generally become slurries, which enter the slurry tank for storage. Storage temperatures generally drop to 80 degrees Celsius.

4. Cocoa Butter Press Machine

This hydraulic oil press has a high oil output rate and is also suitable for the production of peanut oil, sesame oil and almond oil. High hardness and high strength.

5. Chocolate Refiner Machine

The refiner finely grinds the chocolate slurry, which has the dual functions of grinding and refining, and achieves fine granularity and meets the requirements of chocolate production and manufacturing technology.

6. Stirring and Homogenizing Machine

Homogeneity can be achieved by continuous stirring with a stirring machine.

7. Small Scale Chocolate Making Machine

Chocolate moluding machine is a special equipment for quantitative pouring of chocolate. It has functions of automatic pouring, automatic drying, vibration and cooling. It can make a variety of chocolate types such as single color, double color, and filled chocolate.

The sterilization process is also essential. These are some of the equipment needed from cocoa beans to chocolate. There are also some auxiliary equipment, not listed above.

Advantages of Chocolate Making Machine for Small Business

- Specialized production line, excellent craftsmanship, guarantee the quality of finished chocolate.

- The whole set of equipment is easy to control and easy to operate.

- The chocolate is well formed and the pouring quantitative control is accurate.

- Small output, low cost and low investment.

We can configure the entire chocolate making equipment according to customer requirements. Just tell me your needs, email: serena@machinehall.com

If you need a larger capacity chocolate making machine, please check:

Technical Data

| No. | Name | Capacity | Power |

| 1 | Cocoa Bean Roaster(Electric) | 180-250kg/h | 18kw |

| 2 | Cocoa Peeling Machine | 300-500kg/h | 1.5+0.75kw |

| 3 | Cocoa Grinding Machine | 200 kg/h | 7.5 kw |

| 4 | Storage Tank | 200L | 4kw |

| 5 | Conche Machine | 200L | 11kw |

| 6 | Mixing Tank | 200L | 0.75+4kw |

| 7 | Chocolate Bar Making Equipment | 6-15mould pieces/min | 6kw |