Automatic Peanut Candy Bar Production Line 200-500 KG/H

Material: Peanuts, sugar, etc.

Capacity: 200-500 KG/H

Loading Port: Qingdao Port

Description: The entire production line of peanut candy bar, from roasting to packaging. High quality and stable operation.

Product Features

The Peanut Candy Production Line is an automated solution that can easily and efficiently produce high-quality peanut bar and various nut bars in large quantities. The complete set of equipment includes roasting machines, peeling machines, pressing machines, cutting machines and packaging machines. The whole line has perfect technology, stable operation and high quality finished products.

The Peanut Candy Bar Production Process:

Peanuts - roasting and cooling - (peeling) - cooking sugar - stirring - pressing and forming - cutting into pieces - packaging

1. The roasting and cooling stage ensures that the peanuts are evenly roasted and then cooled to the right temperature for optimal flavor and texture. The drum peanut roasting machine is often used

2. The peeling stage is done using a peanut peeling machine that removes the skin of the peanuts. This step is optional because in some processes it is not involved.

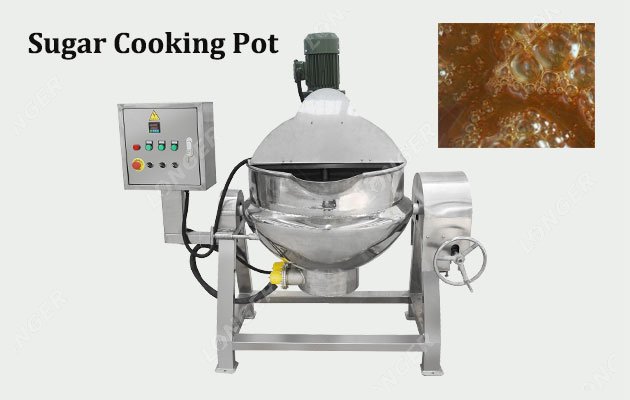

3. The sugar cooking stage involves heating the sugar to the right temperature, mixing it with an appropriate amount of water or oil, and then boiling it into a syrup.

4. The stirring stage is done using a mixer that stirs the sugar and peanuts together, ensuring that the candy is evenly mixed. The machine has fast mixing speed and good heat preservation effect.

5. The pressing stage involves pressing the mixture into shape, forming a hard peanut candy.

6. The cutting stage is done using a high-precision machine that cuts the peanut candy into perfect pieces of uniform size.

The automatic peanut candy making machine integrates mixing, pressing, cooling and cutting functions. This machine can produce peanut candy in various sizes such as rectangular and square. It is also suitable for the production of oatmeal bars, sesame candy, granola bars, energy bars, protein bars, chikki, etc.

7. The packaging stage involves packaging various sizes of peanut candy bar into suitable containers for sale or distribution.

Advantages of this Peanut Bar Production Line

1. High production capacity, efficient processing of ingredients. The production capacity of the entire line can reach 500 kg/h.

2. Safety and hygiene. The conveyor belt is made of PVC and the machine is made of stainless steel, which meets food production requirements. Machine material can also be customized.

3. Adjustable peanut candy size. Easily control finished product size by adjusting the cutter.

4. Wide range of applications: This production line can also be used to produce various snack bars, such as granola bars, cereal bars, energy bars, etc.

5. Operational safety. It also comes with a range of safety features to ensure that the production process is safe for operators.

In short, the Automatic Peanut Candy Production Line is an efficient and reliable production line that can produce high-quality peanut bar cost-effectively. Its range of features and benefits make it ideal for small and medium-sized confectionery factory manufacturers.

Contact Us:

The Peanut Candy Bar Production Process:

Peanuts - roasting and cooling - (peeling) - cooking sugar - stirring - pressing and forming - cutting into pieces - packaging

1. The roasting and cooling stage ensures that the peanuts are evenly roasted and then cooled to the right temperature for optimal flavor and texture. The drum peanut roasting machine is often used

2. The peeling stage is done using a peanut peeling machine that removes the skin of the peanuts. This step is optional because in some processes it is not involved.

3. The sugar cooking stage involves heating the sugar to the right temperature, mixing it with an appropriate amount of water or oil, and then boiling it into a syrup.

4. The stirring stage is done using a mixer that stirs the sugar and peanuts together, ensuring that the candy is evenly mixed. The machine has fast mixing speed and good heat preservation effect.

5. The pressing stage involves pressing the mixture into shape, forming a hard peanut candy.

6. The cutting stage is done using a high-precision machine that cuts the peanut candy into perfect pieces of uniform size.

The automatic peanut candy making machine integrates mixing, pressing, cooling and cutting functions. This machine can produce peanut candy in various sizes such as rectangular and square. It is also suitable for the production of oatmeal bars, sesame candy, granola bars, energy bars, protein bars, chikki, etc.

7. The packaging stage involves packaging various sizes of peanut candy bar into suitable containers for sale or distribution.

Advantages of this Peanut Bar Production Line

1. High production capacity, efficient processing of ingredients. The production capacity of the entire line can reach 500 kg/h.

2. Safety and hygiene. The conveyor belt is made of PVC and the machine is made of stainless steel, which meets food production requirements. Machine material can also be customized.

3. Adjustable peanut candy size. Easily control finished product size by adjusting the cutter.

4. Wide range of applications: This production line can also be used to produce various snack bars, such as granola bars, cereal bars, energy bars, etc.

5. Operational safety. It also comes with a range of safety features to ensure that the production process is safe for operators.

In short, the Automatic Peanut Candy Production Line is an efficient and reliable production line that can produce high-quality peanut bar cost-effectively. Its range of features and benefits make it ideal for small and medium-sized confectionery factory manufacturers.

Contact Us:

Email: serena@machinehall.com

WhatsApp/Mobile: +8615515597212

Technical Data

| Peanut Brittle Production Line | |||

| No. | Name | Power | Dimension |

| 1 | Peanut Roaster machine | 5.5KW | 2900*4700*1650 |

| 2 | Peanut Peeler machine | 1.5KW | 1200*500*1200mm |

| 3 | Sugar Melting Pot | 3KW | 1540*1115*1050mm |

| 4 | Peanut Brittle Making Machine | 6.1KW | 6200*1400*1200mm |