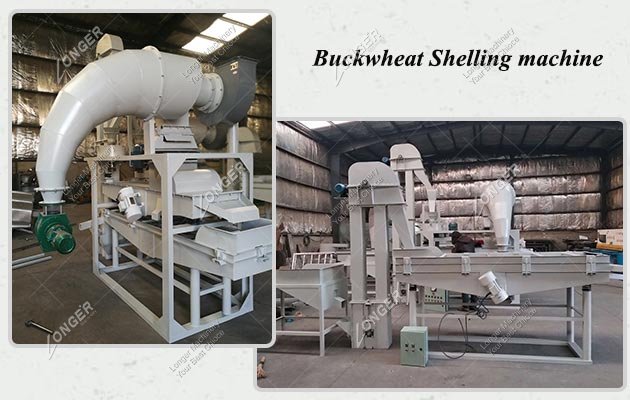

Commercial Buckwheat Grain Shelling Machine Line 400 kg/h

Material: Buckwheat Grain

Capacity: 200-600 kg/h

Loading Port: Qingdao Port

Description: The buckwheat sheller machine is mainly for husking triangle buckwheat and seperating kernels. Fully automatic, large capacity and cheap factory price.

Product Features

This buckwheat shelling machine is a multifuntional grain shelling line, has cleaning, hulling and grading functions. It has a high degree of automation, realizes continuous processing, and has a very good shelling effect. The sheller is the best equipment for processing buckwheat grain.

Cleaning & grading unit: on the hopper, raw material hoist, multi-function machine, bucket elevator, grading machine and electronic control cabinet.

Functions of Buckwheat Grain Shelling Machine

Cleaning and grading machine can clean the buckwheat, remove all kinds of impurities, such as small and light miscellaneous, stones, glass, clods, etc.

Buckwheat is then divided into seven levels according to size (customizable according to customer requirements);

Shelling and sorting unit: It can be used for hulling every level buckwheat, grain hulls separation, buckwheat sorting and so on.

Structure of 400 kg/h Buckwheat Shelling Line

Shelling unit consists of hopper, material hoist, hulling machine, seed sorting sieve, sieve plate combination, hopper, cabinet and other equipment.

Cleaning & grading unit: on the hopper, raw material hoist, multi-function machine, bucket elevator, grading machine and electronic control cabinet.

Functions of Buckwheat Grain Shelling Machine

Cleaning and grading machine can clean the buckwheat, remove all kinds of impurities, such as small and light miscellaneous, stones, glass, clods, etc.

Buckwheat is then divided into seven levels according to size (customizable according to customer requirements);

Buckwheat hulling process: buckwheat feeding → lifting → shelling → separating → buckwheat kernel

Characteristic of Commercial Buckwheat Shelling Machine:

- Sheller is made of full carbon steel and the impeller is made of 99% alumina ceramic, which improves the shelling effect and prolongs the service life.

- It can carry out the shelling and sorting of the buckwheat. A variety of buckwheat evenly shelling.

- The left unshelled grains can be automatically returned to the sheller for the second shelling, which greatly improves the degree of automation.

- Fully automatic, low energy consumption, compact structure, small occupied space, less seed loss, and easy operation and maintenance.

- 400 kg/h, 600 kg/h, 800 kg/h, 1000 kg/h etc capactiy for your choice.

Technical Data

| Processing technician | Machine | Quantity |

| Shelling Unit | Input Hopper | 3 |

| Elevator | 3 | |

| Dehuller | 3 | |

| Sorting sieve section | 3 | |

| Control cabinet | 2 | |

| Cleaning&Grading | Input Hopper | 1 |

| Elevator | 1 | |

| Multifunctional impurity remover | 1 | |

| Elevator | 1 | |

| Classification unit | 3 | |

| Control cabinet | 1 |