Automatic Roasted Nuts Packaging Machine 15-80 Bags/Minute

Material: Roasted Nuts, Mixed Nuts

Capacity: 15-80 Bags/Minute

Loading Port: Qingdao Port

Description: Automatic weighing and packaging of various roasted nuts, such as peanuts, almonds, cashews, sunflower seeds, mixed nuts.

Product Features

This automatic nuts packaging machine is suitable for automatic weighing and packaging of various roasted nuts, such as peanuts, almonds, cashews, sunflower seeds, mixed nuts and other granular materials. It features high precision and high speed, up to 80 bags per minute, PLC control and easy operation. It can be equipped with zipper bags, stand-up bags and other packaging effects to meet your different needs.

The equipment adopts a modular design and is mainly composed of the following key parts:

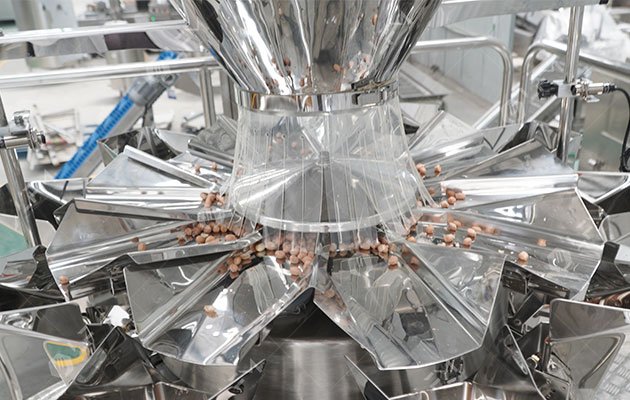

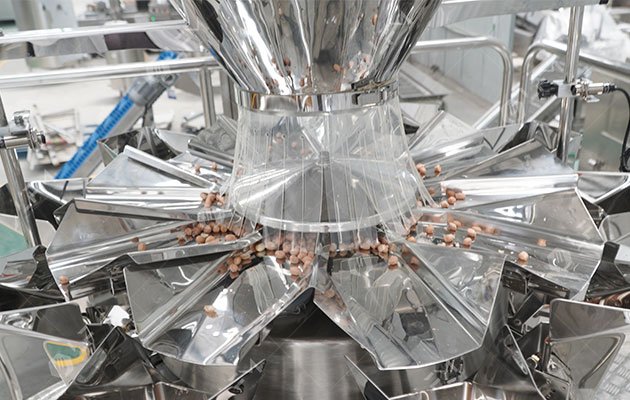

1. Multi-head combination weigher: The core part is equipped with multiple high-speed and high-precision weighing heads. Each weighing head works independently and cooperates with each other. Through advanced algorithms, dynamic optimization combination is achieved. Even when facing nuts with different shapes and densities, accurate weighing can be completed quickly.

2. Material conveying system: A dust-free conveyor belt is used to ensure that the nuts are not contaminated during the conveying process. At the same time, it is equipped with an intelligent diversion device to automatically adjust the flow rate according to the weighing results to ensure continuous and stable material supply.

3. Packaging machine host: It can automatically complete a series of packaging processes such as bag taking, date printing, bag opening, metering, filling, and sealing, and adapt to packaging requirements of different specifications.

4. Control system: Equipped with a touch-screen human-machine interface, the operation is intuitive and simple, and supports parameter presets, fault alarms, data statistics and other functions, making production management more intelligent and efficient.

•Precise cost control: Accurate measurement reduces raw material waste, while high-efficiency design reduces energy consumption and optimizes the production cost structure from the source.

•Guarantee food safety: Materials and designs that comply with international food safety standards ensure the purity and health of nut products and enhance consumer trust.

•Easy to operate and monitor: User-friendly operation interface supports remote monitoring and data analysis, making production management simpler and more intuitive.

Structural Introduction of Roasted Nuts Packaging Machine

The equipment adopts a modular design and is mainly composed of the following key parts:1. Multi-head combination weigher: The core part is equipped with multiple high-speed and high-precision weighing heads. Each weighing head works independently and cooperates with each other. Through advanced algorithms, dynamic optimization combination is achieved. Even when facing nuts with different shapes and densities, accurate weighing can be completed quickly.

2. Material conveying system: A dust-free conveyor belt is used to ensure that the nuts are not contaminated during the conveying process. At the same time, it is equipped with an intelligent diversion device to automatically adjust the flow rate according to the weighing results to ensure continuous and stable material supply.

3. Packaging machine host: It can automatically complete a series of packaging processes such as bag taking, date printing, bag opening, metering, filling, and sealing, and adapt to packaging requirements of different specifications.

4. Control system: Equipped with a touch-screen human-machine interface, the operation is intuitive and simple, and supports parameter presets, fault alarms, data statistics and other functions, making production management more intelligent and efficient.

Features of Automatic Nuts Packaging Machine:

- Easy to operate: PLC control, human-machine interface;

- Quick bag opening: Automatically adjust the suction cup to open the bag, quick bag opening, strong suction of the suction cup;

- Easy bag width adjustment: controlled by the motor, only one button is needed to adjust each group of machine clamps synchronously;

- No bag or incomplete bag opening, no material addition;

- No bag or no material addition, no sealing;

- Door opening shutdown alarm (optional);

- Insufficient air pressure, alarm prompt;

- Abnormal sealing temperature, alarm prompt;

- The part in contact with the material is made of 304/316 stainless steel or food-grade plastic, which meets the hygiene requirements.

Advantages of Roasted Nuts Packaging Machine

•Significantly increase production capacity: Compared with traditional packaging methods, multi-head combination scale packaging machines have a high degree of automation, significantly increase the packaging speed per unit time, and are suitable for large-scale continuous production.•Precise cost control: Accurate measurement reduces raw material waste, while high-efficiency design reduces energy consumption and optimizes the production cost structure from the source.

•Guarantee food safety: Materials and designs that comply with international food safety standards ensure the purity and health of nut products and enhance consumer trust.

•Easy to operate and monitor: User-friendly operation interface supports remote monitoring and data analysis, making production management simpler and more intuitive.

Technical Data

| Model | LG-LK420 |

| Film width | max 420mm |

| Bag width | 80-200mm |

| Bag length | 50-300mm |

| Packing speed | 15-80bags/min |

| Packing range | 150-1500ml |

| Film thickness | 0.04-0.10mm |

| Power | 2.5kw/220v 50-60Hz |

| Machine size | 1400*970*1700mm |

| Machine weight | 450kg |

| Air consumption | 0.4m³/min 0.6mpa |

Leave Your Message

Related Projects

Prev:None

Next:Almond Powder Flour Pouch Packaging Machine Fully Automatic